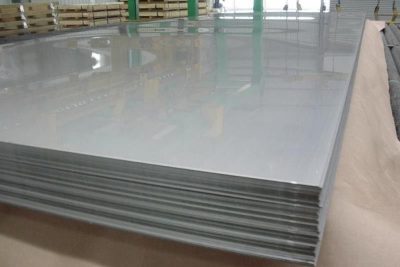

Similar to galvanized steel, Galvalume is produced by a hot-dip process. Instead of 100% zinc, the dip is 55% aluminum, 43.5% zinc and 1.5% silicon. Galvalume Steel Coil have excellent performance, possessing ideal comprehensive properties of corrosion resistance, formation and coating.

Galvalume Steel (also called Aluzinc Steel) are mainly used in building, automobiles, metallurgy, electric equipments and more.

- Building – roof, door, window, roller shutter door and suspended skeleton

- Automobiles – vehicle shell, chassis, door, trunk lid, oil tank, and fender

- Metallurgy – steel sash blank and color coated substrate

- Electric equipements – refrigerator base and shell, freezer, and kitchen equipment

As a leading galvalume steel coil manufacturer, GRSSteel adheres to strict quality standards to produce our galvalume steel coils/sheets. We guarantee our products meet our customer’s requirement.

Specifications

| Technical Standard | ASTM DIN GB JIS3302 |

| Grade | SGCC SGCD or Customer’s Requirement |

| Type | Commercial Quality/DQ |

| Thickness | 0.13mm-4.0mm |

| Width | 600mm-1500mm |

| Type of Coating | Hot Dipped Galvanized |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation/skin pass/non-oiled/oiled |

| Surface Structure | Zero Spangle / Mini Spangle / Regular Spangle / Big Spangle |

| ID | 508mm/610mm |

| Coil Weight | 3-10metric ton per coil |

| Package | Standard export package or customized |

| Hardness | HRB50-71 ( CQ Grade ) |

| HRB45-55 ( DQ Grade ) | |

| Yield Strength | 140-300 (DQ Grade) |

| Tensile Strength | 270-500 (CQ Grade) |

| 270-420 (DQ Grade) | |

| Elongation Percentage | 22 (CQ Grade thickness less 0.7mm) |

| 24 (DQ Grade thickness less 0.7mm) |

Production Line

The annual capacity of Galvanized/Galvalume Line is 320,000 tons. We adopt the UEC hot dip galvanizing process which is the most advanced and wildly used in the world. The main specification of product is 0.15~1.5mm X 800~1250mm.

We could manufacture high performance GI/GL with high zinc coating, non-spangle, minium spangle, regular spangle or big spangle along with the advanced processing of oiled and skin-passed. The product can be used in building materials and electrical appliance.

Quality Control

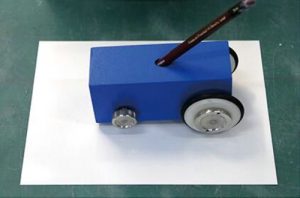

We have our own Physical & Chemical Testing Center Lab. to guarantee our product quality. Our test items & instrument fully meet international standards.

Packing Details

Standard Export Packing:

- 4 eye bands and 4 circumferential bands in steel

- Galvanized metal fluted rings on inner and outer edges

- Galvanized metal and waterproof paper wall protection disk

- Galvanized metal and waterproof paper around circumference and bore protection

About the sea worthy packaging: extra reinforcement before shipment to ensure that the goods are safer and less damaged to customers.