The difference with Galvanized steel:

The difference between galvanized steel and galvalumed steel mainly lies in the difference of coating,the surface of galvanized is evenly distributed with a layer of zinc material, which plays the role of anode protection for the base material. That is to say, the substitute corrosion of zinc material protects the use of raw materials. Only when the zinc is completely corroded can the inner raw materials be damaged.

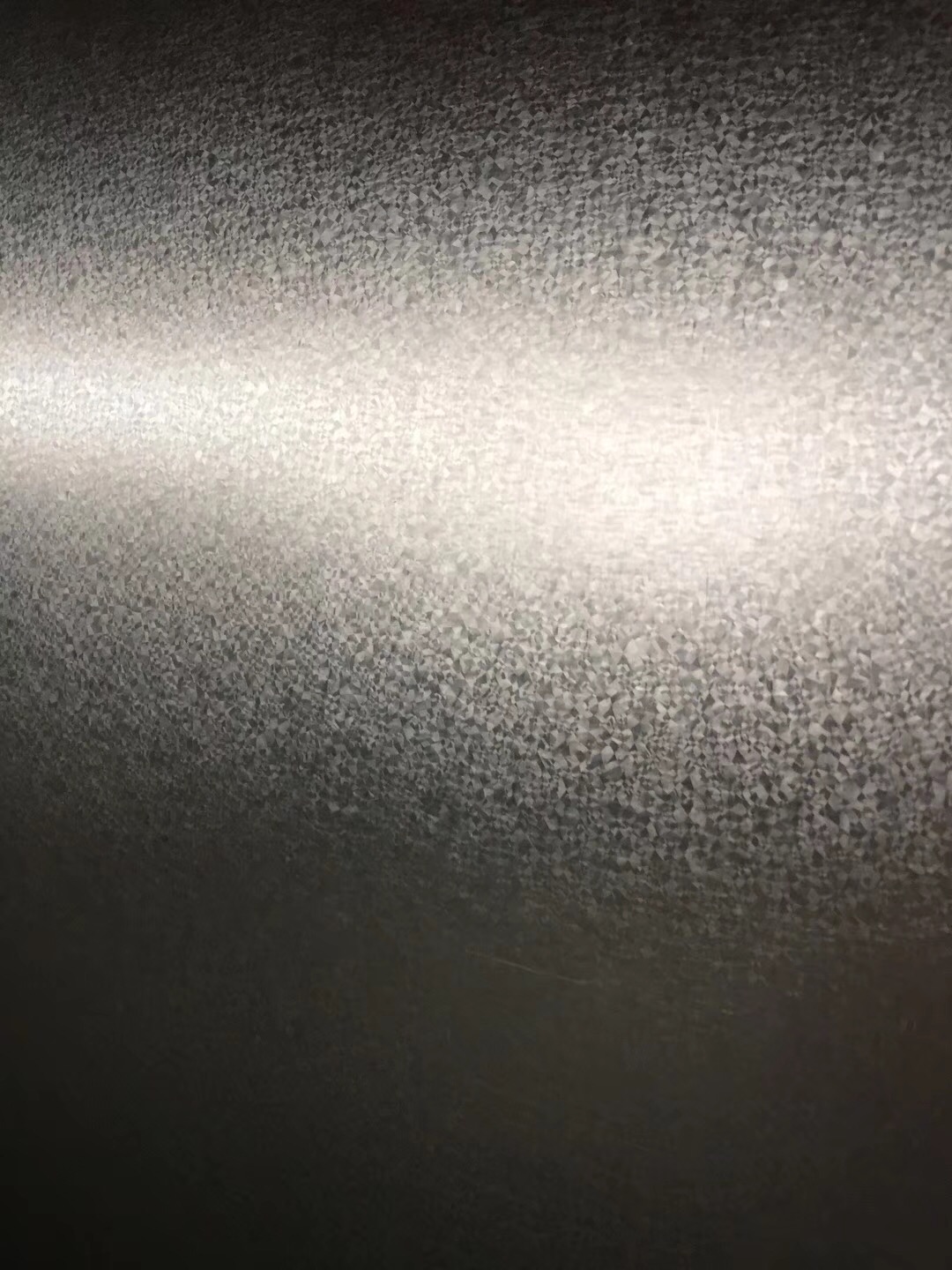

Galvalumed steel the surface of the zinc coating is composed of 55% aluminum, 43.5% of the zinc and small amounts of other elements, aluminum zinc coating under microscopic surface for honeycomb structure, composed of aluminum in the “honeycomb” containing zinc, in this case, Galvalumed steel has anodic protection role, but on the other hand due to the shrinking of zinc content on the one hand, because of the zinc material by aluminum bag not the role of electrolysis anode protection so greatly reduced, so once the Galvalumed steel is cut, the cut off the edge of the protection of basic loss was will soon be under the condition of corrosion, so the plating Galvalumed steel should be cut less as far as possible,Once the edge is protected by anti-rust paint or zinc-rich paint after cutting, the service life of the plate can be extended.

Application

Architecture: roofs, walls, garages, sound barriers, plumbing and modular houses

Automobile: muffler, exhaust pipe, wiper accessories, fuel tank, truck, etc

Home appliances: refrigerator backplate, gas stove, air conditioner, electronic microwave oven, LCD frame, CRT explosion-proof belt, LED backlight, electric cabinet, etc

Agriculture: pig house, chicken house, granary, greenhouse pipe, etc

Others: heat off heat preservation cover, heat exchanger, dryer, heater, etc