1. Main Used

Hot galvanized sheet is mainly used in automobile, home appliances, construction, machinery, electronics, light industry and other industries.

2. Steel Galvanized Classification

Steel factory galvanized products have galvanized, hot dip galvanized two kinds of methods, and these two kinds of subdivision again, galvanized from the zinc layer thickness is divided into single side, double side and poor thickness coating three kinds, and hot dip galvanized is no single side and poor thickness coating, but hot dip galvanized is divided into galvanized and galvanized ferroalloy, electroplating is no zinc ferroalloy.Plating on the kind of plating coating and extend to the electric galvanized, galvanized iron, galvanized tin, plating, galvanized extension is more, including galvanized, zinc iron, aluminum zinc, zinc aluminum, and zinc aluminum magnesium.

3. Annealing Method

There are two kinds of annealing methods for conventional cold rolling coated products: continuous annealing and cover annealing.

4. Common Steel

Product types: general commercial coil (CQ), deep drawing hot galvanized sheet (DQ), super deep drawing hot galvanized sheet (ddq-eddq /SEDDQ), structure galvanized sheet (HSLA), baking hardened hot galvanized sheet (BH), duplex steel (DP), TRIP steel (phase-change induced plastic steel), and multiphase steel (CP).

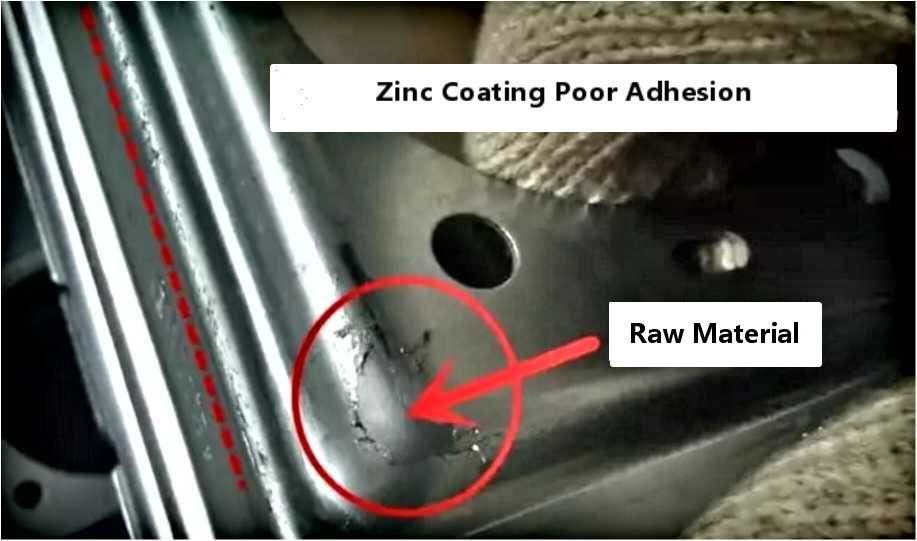

5. Defects of hot-dip galvanizing

Zinc layer peeling, scratch, passivation spot, zinc particles, thick edge, air knife striations, air knife scratches, exposed steel, inclusions, mechanical damage, poor steel base performance, wavy edge, bending, size, imprinting, zinc layer thickness, etc.

6. The main reason of zinc layer shedding

The main reason of zinc layer falling off is raw material production and processing mismatching.Raw materials for surface oxidation, silicon compounds, NOF section of high oxygen atmosphere and dew point of shielding gas, air-fuel ratio is not reasonable, hydrogen flow rate is low, the stove aerobic infiltration, into the pot temperature is low, NOF section of furnace temperature is low, oil evaporation is endless, zinc pot aluminum content is low, the unit too fast, inadequate reduction, in zinc liquid residence time is too short and thick coating.Machining mismatches have bending radius, mold wear, scratch, mold gap is too large or too small, less pressing lubricating oil, mold working time is too long without repair and maintenance.