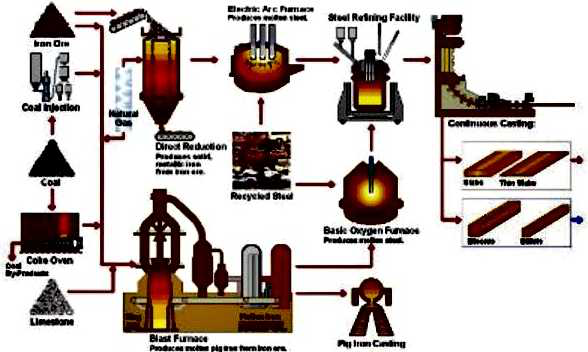

Steelmaking

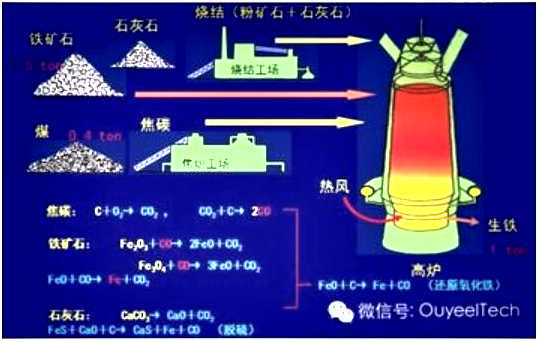

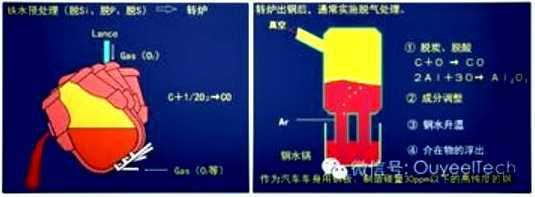

Iron ore is reduced to molten iron, and the specified chemical composition of molten steel is obtained by adjusting the content of alloying elements in the molten iron.

The C, Si, Mn, P, S and other alloying elements we see in the warranty have been basically fixed in this link.

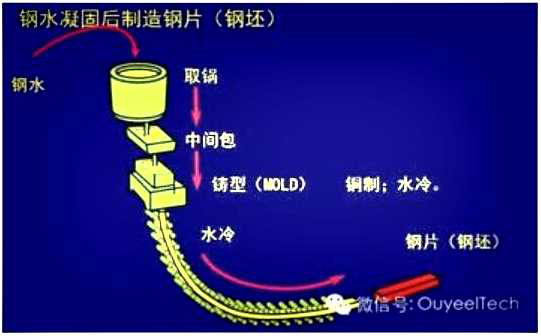

Continuous casting

Direct casting of molten steel into rectangular billets eliminates the traditional “ingot – billet rolling” process.(like 300 tons of molten steel in a furnace, cast into 10 or so rectangular billets.)

The steel blank is the raw material for the hot rolling process.

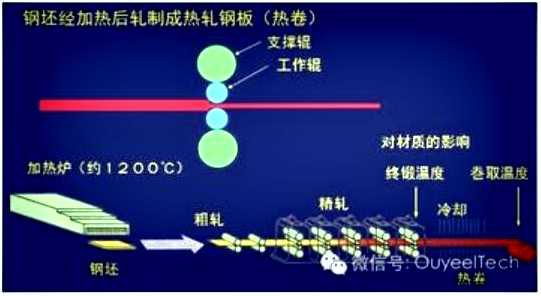

Hot rolled

Hot rolling, or hot rolling.After the billet is heated, it is rolled in a specific temperature range to obtain the desired properties.Main applications: container, engineering machinery, steel structure, etc.

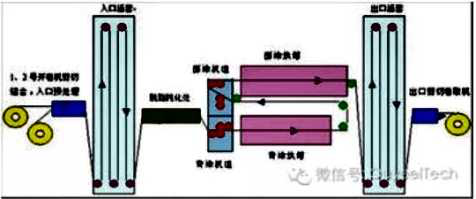

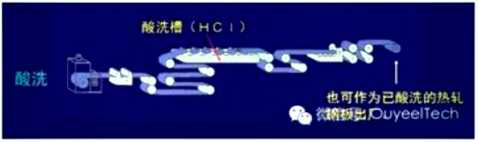

Pickling

A process after hot rolling and before cold rolling is to remove iron oxide from the surface of hot rolling products.The full name of pickling products is “hot rolling pickling material”, which belongs to a kind of hot rolling products.Main applications: automotive chassis parts, wheel hub, electric water heater components

Cold rolled

On the basis of the hot rolled raw material, further thin, to achieve the desired thickness of the finished product.After cold rolling steel strength, hardness, toughness and plastic index decline, processing performance is very poor.

Main applications: cold rolled coils are used as raw materials for subsequent annealing and galvanizing processes.

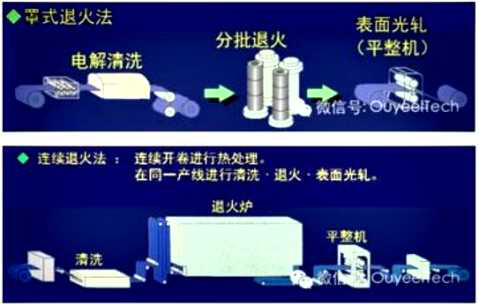

Annealing

The rolled coil is slowly heated to a set temperature, held for a certain time, and then cooled at a specified rate.Annealing is a form of heat treatment designed to obtain desired product properties (mechanical properties).

Main applications: automobiles, home appliances, etc.

Hot dip galvanized

Also known as hot dip galvanizing, the process of dipping the annealed steel strip into a zinc pot containing liquid zinc to obtain a pure zinc or zinc ferroalloy coating on the surface of the steel strip.Main applications: automotive, home appliances, parts with high corrosion resistance.

Electric galvanized

The process of obtaining a thin layer of zinc on the surface of steel strip by electrolysis reaction.

Main applications: computer cases, copiers and other parts of high surface quality requirements.

Colour Coated

The process of coating steel strip with organic or inorganic coatings.

Main applications: industrial plants, mobile buildings, etc.